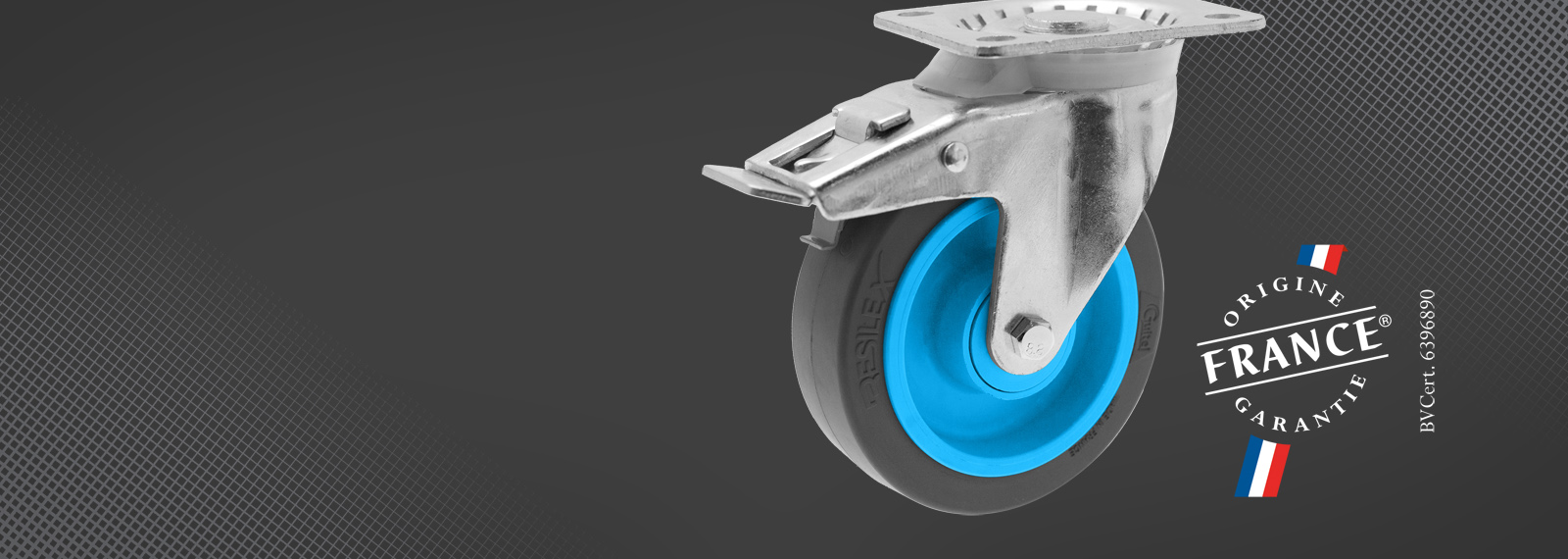

A new design, RESILEX® is manufactured in France and still robust, with good abrasion resistance.

– Logistics

– Manufacturing

– Events

– Catering

– Refrigerating / curing

– Hospital

Requiring reduced starting force, the RESILEX® castor combines full manoeuvrability with optimum user convenience.

It negotiates obstacles effectively, with a very low noise level.

Your guarantee of quality

The elasticity under load of RESILEX® goes hand in hand with full and immediate recovery of the original shape once the load is removed.

More elastic rubber

More elastic rubber

RESILEX HARDNESS 68 SHORE A NON-MARKING TYRE

Generates less noise when in motion

Negotiates obstacles with ease

Changes of direction are easier and smoother

See more

A more efficient bearing

A more efficient bearing

HUB WITH BALL BEARINGS

LONG-LIFE, 2RS WATERTIGHT LUBRICANT

A reduced contact area prevents overheating

Improved axial and radial load capacity

Precision ball bearing with long-life dust- and splash-resistant grease

See more A protective thread guard

A protective thread guard

UNBREAKABLE DOUBLE-LIP POLYAMIDE 6

Provides full dust- and splash-proof protection for the bearing

Forms an integral part of the wheel element in contact with the inner race of the bearing

Prevents dirt from being wound around the axle

See more A high-quality bearing element

A high-quality bearing element

UNBREAKABLE POLYAMIDE 6

HYDROCARBON-RESISTANT MATERIAL

Mechanical properties offer resistance to impacts and to standard petroleum products and solvents

Assembly of the different components is optimised through:

– The undermoulding of the element and bonding with the tyre

– The overmoulding with the ball bearing